STEP 1: Preparation and Planning

In this phase, the location and customer requirements are mapped out. Based on drawings and measurements, it is determined which equipment is needed where and how ventilation can best be controlled. This results in an installation plan for each room.

STEP 2: Logistical Preparation

All necessary components are collected, checked, and pre-configured where possible. The materials are transported to the location and the installer verifies that everything is complete.

Step 3 – On-Site Installation

Ventilation units, sensors, and other equipment are mounted and connected. The devices are then activated and connected to the network, making them ready for use.

Step 4 – Configuration and Calibration

Sensors are calibrated and ventilation settings are adjusted to the on-site situation. The system is tested for functionality and reliability. The installer confirms correct installation with a checklist.

Step 5 – Delivery and Handover

Users receive instructions on the system and its operation. A delivery report is prepared and the system is placed in active monitoring. Maintenance and filter changes are automatically scheduled.

Our Product Code Explained

Each AerosFair unit is equipped with a unique product code that provides essential information about the device or unit at a glance. The code consists of multiple parts, each with a specific meaning.

- AEROS – Brand identification.

- B1 – Type designation of the model or variant.

- 25 – Production year, in this case 2025.

- Y7 – Reference to the production batch, for quality assurance and traceability.

- 381 – UID (Unique ID); a generated unique code within the batch.

- 4553 – AAID (AerosFair Assembly ID); link to the assembly line or specific production unit.

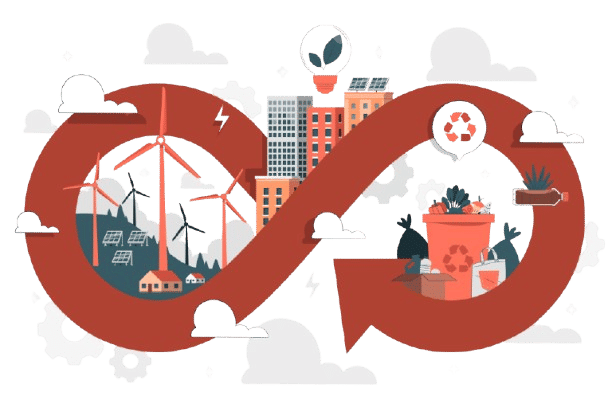

Energy Transition and the Role of AerosFair

Within AerosFair, the process of smart ventilation is a crucial part of our contribution to the energy transition. It begins with identifying the specific ventilation needs of a space, which is done by our advanced sensors that monitor data such as temperature, humidity, and CO2 levels. This data is processed in real-time by our self-learning technology, which optimizes ventilation based on actual needs. This prevents unnecessary energy waste by only activating the required ventilation capacity. Additionally, it reduces CO2 emissions by dynamically controlling ventilation systems, rather than manually or continuously running systems without considering the actual situation.

This process directly contributes to the broader goals of the energy transition, where efficient energy use and sustainability are central. Our technology thus not only provides direct benefits for air quality but also plays an important role in reducing the ecological footprint of buildings, helping businesses, schools, and other institutions reduce and make their energy consumption more sustainable.

Comfort tailored to you, exactly as you want it.

How Aerosfair Provides Targeted Comfort Against Cold Downdrafts in Classrooms and Offices

Optimize business ventilation with AerosFair healthy efficient and sustainable for a better future

Why AerosFair Is Essential For Healthy Indoor Air

Optimize business ventilation with AerosFair healthy efficient and sustainable for a better future

Why Ventilation Should Not Be an Afterthought for Healthy Air in Classrooms

Good air quality is not a luxury, but a prerequisite for health and learning performance.

Breathing space in the polluted outdoor air of the Netherlands

Optimize business ventilation with AerosFair healthy efficient and sustainable for a better future

Healthy Workspaces

Optimize business ventilation with AerosFair healthy efficient and sustainable for a better future